Patented Products

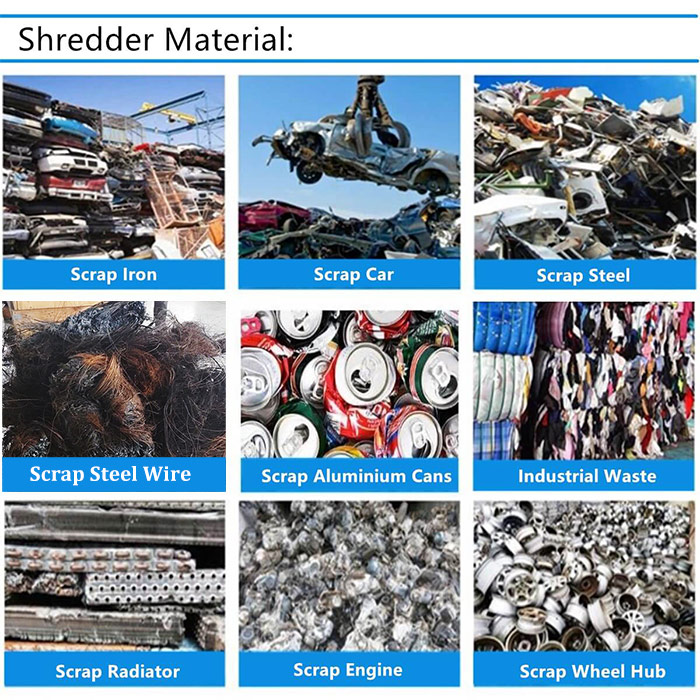

Applicable Material : pyrolysis tire steel wire, tire steel wire waste, steel wire, paint drums, diesel drums, thin iron sheets, car shells, metal briquettes, metal plate scraps, and other scrap metal materials.

A pyrolytic steel wire vertical crusher is a vertical crushing device specifically designed for shredding the steel wire residue produced by the pyrolysis of scrap tires (or other polymer materials containing steel wire). It is a core crushing device in a pyrolytic steel wire recycling line. Designed to address the unique characteristics of the pyrolytic material (which contains a mixture of components such as steel wire, carbon black, and rubber crumbs, with strong adhesion and wide variations in hardness), it achieves efficient separation of steel wire from carbon black/rubber through vertical power transmission and impact/shear crushing mechanisms. It also reduces the steel wire or mixed components to the target particle size (typically below 50mm, facilitating subsequent magnetic separation, fine crushing, or cleaning).

In the pyrolytic steel wire recycling process, this device is typically located after pretreatment and before magnetic separation. It is a key component for the initial crushing of large residues (such as the lumpy mixture after pyrolysis), directly impacting subsequent steel wire separation efficiency and overall recovery rate.

Pyrolytic Wire Vertical Crusher Structure:

• Vertical Casing: A vertical cylindrical or conical container (made of Q235B or stainless steel lining) with a top feed inlet and a bottom discharge outlet. The inner wall is inlaid with a wear-resistant lining (such as high-manganese steel or polyurethane) to reduce material impact wear.

• Spindle System: A vertically arranged high-strength alloy steel spindle (fixed to the top/center of the casing via a bearing block) is driven by a motor via a pulley or reducer (typically 1000-3000 rpm, adjustable depending on the crushing requirements).

• Core Components: The rotor assembly (consisting of a disc and hammer/throwing head) is mounted at the top of the spindle. The high-speed rotation of the rotor propels the material onto the impact plate or lining on the inner wall of the casing, crushing it through impact.

• Crushing Process: Material falls vertically from the top feed inlet into the center of the rotor, where it is struck and accelerated by the high-speed rotating hammers. It then strikes the wear-resistant lining (or impact plate) on the inner wall of the casing at high speed, causing brittle fracture and separation. The steel wire remains largely intact due to its high hardness, while the carbon black/rubber is shattered by the impact due to its brittleness, thus achieving a preliminary separation of the steel wire from the carbon black/rubber.

• Advantages: High crushing ratio (a single unit can crush 50cm blocks to ≤50mm). When handling adhesive materials, the impact force strips surface coatings. Suitable for high-volume applications (processing capacity of 5-50t/h).

• Discharge Control: The bottom discharge outlet uses a screen plate (or adjustable discharge gap) to control the discharge particle size (e.g., ≤50mm, ≤30mm). Fine material smaller than the screen aperture is discharged directly, while coarse material returns to the crushing chamber for further crushing (closed-circuit circulation).

Whole waste tire machine/fragments: tire blocks, tire rims (including high-hardness steel wire rims), sidewalls, etc. that have not been cracked.

Pyrolysis tire steel wire: the remaining steel wire and rubber mixed mass after the waste tire is thermally cracked or physically crushed, and the steel wire is in a tangled or bonded state.

Tire steel wire waste: separately recycled tire steel wire bundles, steel cords (such as steel cords in radial tires), or other rubber product waste containing steel wire (such as steel wire hoses, conveyor belt scraps).

Other similar materials: metal-rubber composite materials with hardness and toughness close to tire steel wire, such as seals and shock absorbers containing steel wire, but the tool configuration needs to be adjusted according to the equipment specifications.

The pyrolysis steel wire crushing and washing line is an integrated production line for "crushing-separation-purification" of waste steel wire (such as pyrolysis tire steel wire, pyrolysis plastic-metal composite steel wire, etc.) produced after pyrolysis process treatment. Its core function is to remove the pyrolysis residues (such as carbon black, resin, oil, dust, etc.) attached to the surface of the steel wire through physical crushing and dust removal processes, and process the steel wire into pure metal raw materials that meet the recycling standards. It is a key supporting equipment for the recycling of pyrolysis waste materials.

| Type | Capacity (t/h) | Power (kw) |

|---|---|---|

| XRD-LZP-800 | 5 - 15 | 30 |

| XRD-LZP-1000 | 10 - 30 | 55 |

| XRD-LZP-1250 | 17 - 60 | 132 |

| XRD-LZP-1500 | 25 - 80 | 160 |

| XRD-LZP-1750 | 30 - 100 | 200 |

Customizable according to customer needs.