Patented Products

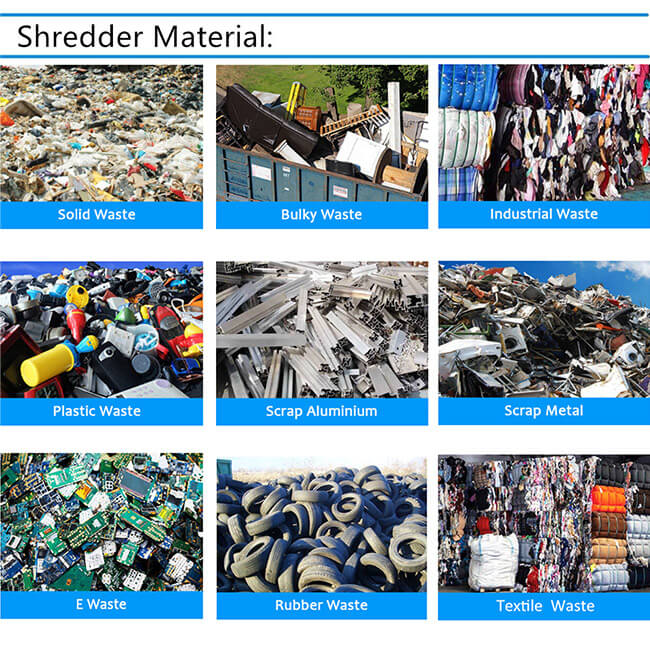

Type : Industrial Shredder, Metal Shredder, Solid waste disposal system.

Product Application : industrial waste disposal industry

Applicable Material : Sponge, Textile, Leather, Wood, industrial waste, Plastics, Waste blue drum, Waste Metal, Solid waste etc.

Industrial shredder: a powerful assistant for industrial waste treatment

Industry waste shredder is a kind of crushing equipment specially designed for processing various types of industrial waste. Through mechanical actions such as shearing, tearing and squeezing, it can break large or irregular industrial waste into smaller materials for subsequent recycling, transportation or harmless treatment.

A modern industrial shredder is a highly efficient, intelligent, and versatile material shredder designed specifically for processing various types of industrial waste, bulky scrap, or high-hardness materials. Its core function is to break large, high-strength, or complex materials (such as metal, plastic, rubber, wood, and electronic waste) into uniform, small pieces (typically 10-100mm in size, adjustable to meet specific needs) through mechanical shearing, squeezing, and tearing. This equipment facilitates subsequent recycling, reprocessing, or environmentally friendly disposal. Integrating modular design, automated control, environmentally friendly technologies, and adaptability for diverse scenarios, this equipment is widely used in resource recovery, solid waste treatment, industrial production, and other fields, making it a key component of the modern industrial circular economy.

The industrial waste processing line developed by Xrido can transform industrial waste into high-quality high calorific value SRF/RDF, which can be used as fuel instead of fire coal, thus realizing the conversion of waste into energy. This processing line is mainly aimed at relatively pure waste leather, commercial waste plastics and other high calorific value solid waste, for more complex waste can be equipped with screen and density air sorting machine to complete the target to be processed. High torque double shearing shredder and special single shaft shredder for SRF/RDF will be used in the system. After secondary shredding, the material size can reach 30-80 mm (based on the requirement), and the standard-reaching rate is higher than 95%.

• Modular Tool System: The tool can be quickly removed and replaced, supporting various tooth profiles (such as corrugated teeth, straight-edged teeth, and serrated teeth) to adapt to different material properties (e.g., plastics require sharp teeth, metals require high-strength teeth);

• Low Speed, High Torque: Compared to traditional crushers (which often operate at speeds >100 rpm), industrial shredders typically operate at lower speeds (10-40 rpm), reducing energy consumption, lowering noise levels (<85 dB), and preventing material overheating and oxidation (especially critical for metal and rubber recycling);

• Intelligent Control: A PLC or industrial computer system monitors operating status (such as tool wear, motor load, and feed speed) in real time, supporting remote operation, fault diagnosis, and automatic alarms, reducing manual intervention.

The structural design of the industrial shredder fully considers the high-intensity and high-load work requirements in industrial production. It is mainly composed of a shredding knife group, a load-bearing frame, a power system, a feeding device and a control system. The shredding knife group is the core component. Depending on the material being processed, the material and shape of the blade will vary. When processing hard materials such as metal, the blade is made of high-strength alloy steel, which has undergone special heat treatment and has extremely high hardness and wear resistance; when processing materials such as plastics and wood, the blade focuses on toughness and shearing ability.

Industrial shredders can crush common industrial solid waste types such as metals (such as scrap steel, aluminum profiles, copper cables), plastics (such as PE, PP, PVC films, pipes), rubber (such as tires, seals), wood (such as tree trunks, furniture waste), electronic waste (such as circuit boards, cables), and composite materials (such as fiberglass, carbon fiber).

Modern industrial solid waste disposal focuses on "reduction, resource utilization, and harmlessness." Through refined classification, efficient crushing and sorting, valuable material recovery, and safe treatment, it achieves full lifecycle management of industrial waste. While the process flow varies slightly depending on the type of solid waste (such as metal, plastic, rubber, electronic waste, and composite materials), it generally follows the principle of "pretreatment → crushing and sorting → resource recovery → residual treatment." By integrating intelligent technologies and environmental protection requirements, it forms an efficient, low-carbon closed-loop system.

Providing one-stop Solution

The company's main products include double-axis shredders, metal crushers, solid waste disposal equipment and renewable resource equipment to meet the needs of different customers. By providing a one-stop solution, XRIDO Group can helps customers solve various solid waste treatment problems.

Industrial shredders have become key equipment in the industrial waste treatment process with their wide range of applications, efficient crushing capacity and stable performance, providing a strong guarantee for resource recycling and sustainable development in the industrial field.

Solid Waste Disposal Process:

Feed: Pretreated solid waste is evenly fed into the twin-shaft solid waste shredder through the feed port. The feed rate can be adjusted based on the equipment's processing capacity and the nature of the solid waste to ensure stable operation.

Crushing: The solid waste entering the shredder is gradually broken down by the shearing, tearing, and squeezing action of the twin-shaft blades. The equipment automatically adjusts the blade speed and torque according to a pre-set program to accommodate materials of varying hardness and toughness. During the crushing process, large solid waste is gradually broken down into smaller pieces.

Discharge: The shredded, smaller pieces are discharged through the discharge port and into the discharge hopper. The discharge hopper can be equipped with a screen to screen the discharged material, returning any that does not meet size requirements to the shredder for further crushing.

Sorting: The discharged shredded material can undergo further processing, such as cleaning, drying, magnetic separation, or sorting, according to subsequent processing requirements. Cleaning can remove dirt and impurities on the surface of the material, drying can reduce the water content of the material, magnetic separation can separate the metal materials in the material, and sorting can separate different types of materials for recycling or subsequent processing.

| Model | Overall Size(mm) | Crushing Cavity Size(mm) | Power(kw) | Weight(kg) |

|---|---|---|---|---|

| XRD - SZSS - 500 | 2800×1300×1850 | 500×480 | 11×2 | 2200 |

| XRD - SZSS - 800 | 3000×1300×1850 | 800×480 | 15×2 | 2500 |

| XRD - SZSS - 1000 | 3300×1900×2200 | 1000×690 | 22×2 | 5200 |

| XRD - SZSS - 1200 | 3600×2000×2200 | 1200×690 | 30×2 | 6400 |

| XRD - SZSS - 1500 | 4100×2100×2400 | 1500×850 | 55×2 | 9000 |

| XRD - SZSS - 1800 | 5800×2400×3300 | 1800×1206 | 75×2 | 13600 |

| XRD - SZSS - 2000 | 6400×2700×3500 | 2000×1490 | 90×2 | 20100 |

| XRD - SZSS - 2500 | 7500×3200×3800 | 2500×1800 | 110×2 | 22500 |

| XRD - SZSS - 3000 | 8600×3500×4000 | 3000×1800 | 160×2 | 31000 |

(Special - customized types can be customized according to the size and type of materials.)