Patented Products

Type : Double Shaft Shredder, Metal Shredder, Solid waste disposal system.

Product Application : Solid waste disposal industry

Applicable Material : Industrial waste, Domestic waste, Scrap metal, Medical waste, Solid waste, Plastic, Wood, Bulky waste, E waste etc.

A modern solid waste shredder is a mechanical device specifically designed for processing various types of solid waste. It uses blades mounted on two counter-rotating shafts to shear, tear, and crush incoming solid waste, breaking large, hard, and irregularly shaped solid waste into smaller, uniformly sized materials for subsequent recycling, processing, or disposal. This equipment integrates advanced mechanical design concepts, automated control technology, and advances in materials science, offering high efficiency, stability, and environmental friendliness, adapting to the processing needs of a wide range of solid waste types.

• Shaft Rotation and Material Entry: A solid waste shredder primarily consists of two parallel shafts, each equipped with several blades. Driven by a motor, the two shafts rotate in opposite directions, generating a powerful shearing force. An operator or conveyor feeds the solid waste to be processed into the shredder's feed port.

• Shearing and Tearing Process: When solid waste enters the space between the two rotating blades, the high-speed counter-rotating blades generate a violent shearing action against the material. Simultaneously, the blades' mutual compression and tearing action gradually shred the material. The optimized blade shape and arrangement effectively grip the material and cut it into small pieces.

• Discharge: The shredded, small-sized material is discharged through the gap between the blades and falls into the discharge hopper below, completing the shredding process. For difficult-to-shred materials, the equipment can adjust parameters such as the blade speed and blade gap to ensure efficient processing.

Core advantages:

Adopting a sturdy and durable dual-spindle design, equipped with high-hardness and high-wear-resistant blades made of special alloy steel.

Low-speed, high-torque rotation generates strong shearing and tearing forces, which can easily crush and process various hard and tough scrap metals.

Whether it is heavy car shells, home appliance shells, bicycle frames, scrap steel and iron, aluminum alloy profiles, copper cables, or oil drums, color steel tiles, metal scraps, etc., they can be efficiently decomposed into uniform and controllable fragments.

• Modular Tool System: The tool can be quickly removed and replaced, supporting various tooth profiles (such as corrugated teeth, straight-edged teeth, and serrated teeth) to adapt to different material properties (e.g., plastics require sharp teeth, metals require high-strength teeth);

• Low Speed, High Torque: Compared to traditional crushers (which often operate at speeds >100 rpm), industrial shredders typically operate at lower speeds (10-40 rpm), reducing energy consumption, lowering noise levels (<85 dB), and preventing material overheating and oxidation (especially critical for metal and rubber recycling);

• Intelligent Control: A PLC or industrial computer system monitors operating status (such as tool wear, motor load, and feed speed) in real time, supporting remote operation, fault diagnosis, and automatic alarms, reducing manual intervention.

Solid Waste Disposal Process:

Feed: Pretreated solid waste is evenly fed into the twin-shaft solid waste shredder through the feed port. The feed rate can be adjusted based on the equipment's processing capacity and the nature of the solid waste to ensure stable operation.

Crushing: The solid waste entering the shredder is gradually broken down by the shearing, tearing, and squeezing action of the twin-shaft blades. The equipment automatically adjusts the blade speed and torque according to a pre-set program to accommodate materials of varying hardness and toughness. During the crushing process, large solid waste is gradually broken down into smaller pieces.

Discharge: The shredded, smaller pieces are discharged through the discharge port and into the discharge hopper. The discharge hopper can be equipped with a screen to screen the discharged material, returning any that does not meet size requirements to the shredder for further crushing.

Sorting: The discharged shredded material can undergo further processing, such as cleaning, drying, magnetic separation, or sorting, according to subsequent processing requirements. Cleaning can remove dirt and impurities on the surface of the material, drying can reduce the water content of the material, magnetic separation can separate the metal materials in the material, and sorting can separate different types of materials for recycling or subsequent processing.

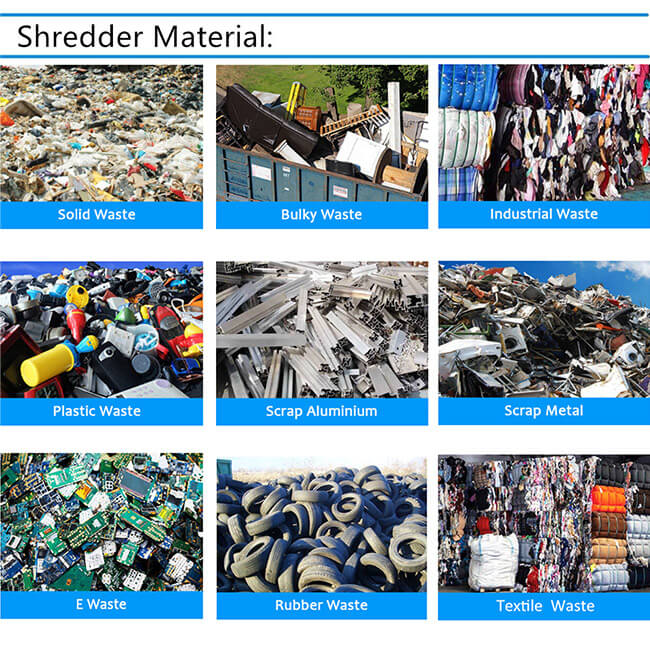

Wide range of applications:

The waste shredder machine can shred nearly all common industrial waste. Typical suitable materials include:

• Metals: scrap steel, aluminum extrusions, copper cables, and stainless steel products (such as appliance casings and industrial scraps);

• Plastics and rubber: waste film (such as PE and PP), plastic pipes, rubber tires, and conveyor belts (including steel cord);

• Composite materials: fiberglass, carbon fiber components, and electronic circuit boards (including plastic-metal composites);

• Other waste: wood scraps, used furniture, fabrics, and cardboard (requiring blade design adjustments). It is particularly adept at processing large, highly resilient, or easily entangled materials (such as rolls of plastic film, bales of scrap metal, and tires), using low shear speeds to prevent rebound and jamming.

Choose our waste shredder machine, you will get:

1. Significant cost reduction: Reduce labor, transportation, and smelting costs.

2. Higher recycling benefits: Produce high-density, high-purity high-quality metal fragments, with higher selling prices.

3. Stronger processing capabilities: Easily handle various complex scrap metal materials.

4. Longer equipment life: Sturdy and durable, high return on investment.

Providing one-stop Solution

The company's main products include double-axis shredders, metal crushers, solid waste disposal equipment and renewable resource equipment to meet the needs of different customers. By providing a one-stop solution, XRIDO Group can helps customers solve various solid waste treatment problems.

Solid Waste Disposal Line:

| Model | Overall Size(mm) | Crushing Cavity Size(mm) | Power(kw) | Weight(kg) |

|---|---|---|---|---|

| XRD - SZSS - 500 | 2800×1300×1850 | 500×480 | 11×2 | 2200 |

| XRD - SZSS - 800 | 3000×1300×1850 | 800×480 | 15×2 | 2500 |

| XRD - SZSS - 1000 | 3300×1900×2200 | 1000×690 | 22×2 | 5200 |

| XRD - SZSS - 1200 | 3600×2000×2200 | 1200×690 | 30×2 | 6400 |

| XRD - SZSS - 1500 | 4100×2100×2400 | 1500×850 | 55×2 | 9000 |

| XRD - SZSS - 1800 | 5800×2400×3300 | 1800×1206 | 75×2 | 13600 |

| XRD - SZSS - 2000 | 6400×2700×3500 | 2000×1490 | 90×2 | 20100 |

| XRD - SZSS - 2500 | 7500×3200×3800 | 2500×1800 | 110×2 | 22500 |

| XRD - SZSS - 3000 | 8600×3500×4000 | 3000×1800 | 160×2 | 31000 |

(Special - customized types can be customized according to the size and type of materials.)