Patented Products

Input Size : Customize

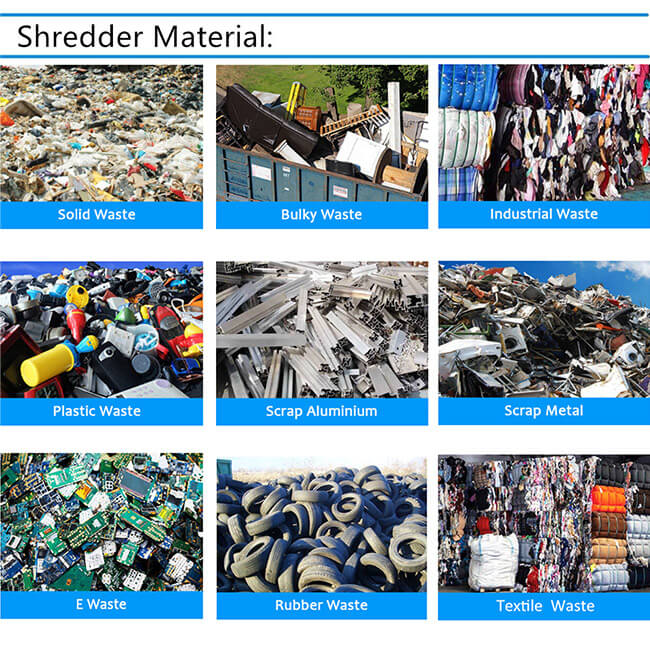

Applicable Material : Plastics: fish net, used plastic bottles, plastic film, plastic barrels, etc.; Rubber: tires and rubber product scraps; Fibers: waste paper, cloth, wood, straw; Small and medium-sized metals: thin iron sheets, aluminum products, etc.

A single-shaft shredder uses a single rotating main shaft to drive the mounted cutting tools. This is achieved through the interaction of a rotating blade and a fixed blade. The motor drives the main shaft, causing the rotating blade mounted on the main shaft to rotate at high speed. After entering the shredding chamber from the feed inlet, the material is sheared, torn, and crushed by the rotating blade. Meanwhile, the fixed blade, fixed within the shredding chamber, works in conjunction with the rotating blade to further enhance the cutting effect, breaking the material into smaller pieces. The crushed material is then discharged through a screen.

Structural Components

• Drive System: This typically consists of a motor and a speed reducer, providing power to the shredder. The motor transmits power to the speed reducer via a pulley or coupling. The speed reducer then reduces the speed and increases the torque, thereby driving the main shaft.

• Spindle System: This is one of the core components of a single-shaft shredder. The blades are mounted on the main shaft. The material and machining precision of the main shaft directly impact the performance and lifespan of the shredder. Driven by the drive system, the main shaft rotates at high speed, driving the blades to shred the material.

• Blade System: Consists of a rotating blade and a fixed blade. The rotating blade is mounted on the main shaft and rotates with it; the fixed blade is fixed to the wall of the shredding chamber. The blades are generally made of high-strength alloy steel, offering excellent wear resistance and sharpness, enabling them to effectively shred a wide range of materials.

• Shredding Chamber: This is the space where the material is shredded and consists of a housing and liner. The proper design of the shredding chamber directly impacts the shredding efficiency and the equipment's production capacity. The liner is typically made of wear-resistant material to protect the housing from wear.

• Feed and Discharge Systems: The feed system is used to evenly feed the material into the shredding chamber. Common feeding methods include manual feeding and conveyor belt feeding. The discharge system is used to discharge the shredded material from the equipment. It typically includes a screen and a discharge port. The screen controls the particle size of the shredded material.

Applications

• Waste Plastic Recycling: Various plastic products, such as fishing nets, plastic film, plastic pipes, and plastic containers, can be shredded for subsequent recycling.

• Metal Recycling: Shreds scrap metal, metal products, and automobile casings, increasing metal recycling rates.

• Electronic Waste Processing: Shreds used electronic products such as computers, mobile phones, and circuit boards to separate valuable metals and components.

• Wood Processing: Shreds waste wood, branches, and tree trunks into sawdust for use in biomass power generation, papermaking, and wood-based panels.

• Domestic Waste Processing: Pre-processes large items of household waste, such as furniture and mattresses, to reduce their volume and facilitate subsequent sorting and processing.

Advantages

• Strong Crushing Capacity: Capable of handling materials of varying hardness, toughness, and viscosity, and even effectively crushing difficult-to-crush materials such as rubber, plastic, and metal.

• High Stability: Its rational structural design ensures stable and reliable operation, enabling long-term continuous operation and minimizing equipment failures and downtime.

• Simple Operation and Maintenance: Operation is relatively simple; simply follow the operating instructions. The equipment is also easy to maintain, with blades and other wearing parts easily replaced.

• Wide applicability: Single-shaft shredders of varying models and specifications can be selected to suit different materials and processing requirements. The particle size of the shredded material can also be controlled by adjusting the blade spacing and screen aperture.

Case

| Model | Blade diameter (mm) | Feed inlet size (mm) | Capacity (kg/h) | Power (kw) | Size (L×W×H) (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| XRD - DZSS - 600 | 260 | 600×550 | 300 - 500 | 15 | 1800×1300×1700 | 2850 |

| XRD - DZSS - 800 | 300 | 800×600 | 500 - 800 | 37 | 2800×1800×2100 | 4200 |

| XRD - DZSS - 1000 | 350 | 1000×700 | 800 - 1500 | 45 | 2800×2000×2100 | 6500 |

| XRD - DZSS - 1200 | 400 | 1200×900 | 1500 - 2500 | 55 | 2800×2500×2100 | 7800 |

| XRD - DZSS - 1400 | 450 | 1400×900 | 2500 - 4000 | 75 | 2800×2800×2100 | 9600 |

| XRD - DZSS - 1600 | 500 | 1600×1000 | 4000 - 6000 | 90 | 3000×2800×2100 | 12500 |

(The capacity varies depending on the characteristics of the materials. )