Patented Products

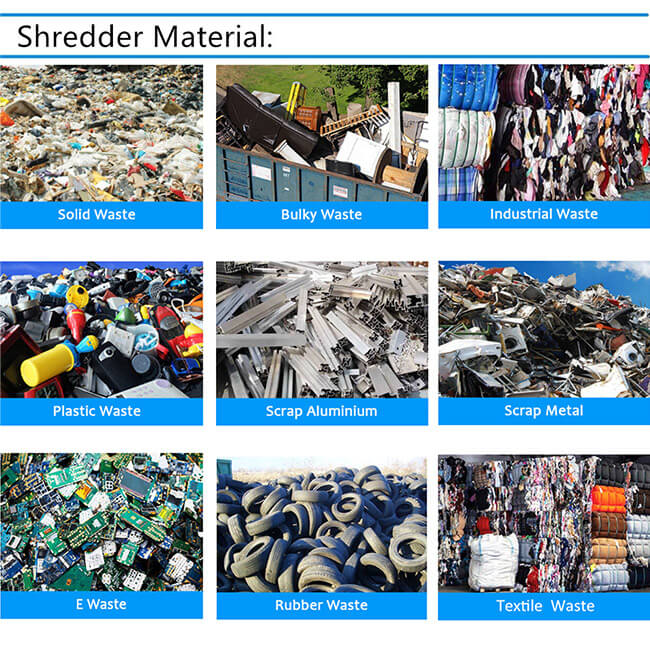

Product Application : Solid waste disposal industry

Applicable Material : Furniture, Mattress, Sofa, Refrigerator, Home appliances, Construction and decoration waste, Other large objects.

A large furniture shredder is a large-scale shredder designed specifically for processing large, complex discarded furniture (such as sofas, mattresses, wardrobes, tables and chairs, etc.). It uses mechanical force to break the furniture into smaller pieces (typically 5-100mm) for subsequent recycling (such as separating wood, metal, and fabric for recycling) or environmentally friendly disposal (such as volume reduction before landfill or incineration).

the large furniture shredder achieves waste reduction, harmlessness, and resource utilization. It is a key piece of equipment in the furniture recycling industry chain, particularly suitable for waste treatment plants, resource recovery centers, and furniture factory waste processing.

The core principle of a large furniture shredder is to break large pieces of furniture into smaller pieces through the shearing, tearing, and squeezing action of high-speed rotating and fixed blades. The specific process is as follows:

1. Feeding Stage: Large pieces of furniture are fed into the shredder's feed port via a conveyor belt or manually. The feed port is typically designed with a large opening (up to 1-3 meters wide) to accommodate furniture of varying sizes. 2. Crushing Stage: The crusher chamber is equipped with multiple sets of rotating cutting tools (such as blades and claws). Driven by a motor, the cutting tools rotate at high speed (typically 50-300 rpm), creating relative motion with stationary cutting tools fixed to the inner wall of the crusher chamber, shearing, tearing, and crushing the furniture.

- For wooden furniture (such as wardrobes, tables and chairs): The cutting tools directly cut the wood, breaking it into chips.

- For fabric furniture (such as sofas and mattresses): The cutting tools first tear the fabric and sponge, then sever the internal metal springs or frames to separate the materials.

3. Discharge Stage: The crushed materials are screened to ensure uniform size and discharged through the discharge port for subsequent recycling.

Core Advantages

1. Efficient Processing of Large Items: For large furniture (such as wardrobes and sofas) that cannot be processed by traditional crushers, this crusher can directly feed and crush the material, eliminating the need for manual disassembly and significantly improving processing efficiency (a single unit can process 5-20 tons per hour).

2. Material Separation: The tool design and crushing process enable preliminary separation of wood, metal, fabric, sponge, and other components within furniture, reducing sorting costs for subsequent recycling.

3. Significant Volume Reduction: Crushing reduces material volume by 50%-80%, saving transportation and storage space and lowering disposal costs.

4. High Adaptability: The tool can handle furniture made of various materials (wood, fabric, leather, metal frames, etc.), and its wear resistance is high, allowing for a long maintenance cycle.

5. Environmental Compliance: The enclosed crushing chamber design reduces dust and noise pollution, meeting environmental standards and preventing environmental contamination caused by indiscriminate waste storage.

Large Furniture Disposal Process:

Feeding:

Large pieces of furniture are fed into the feed port of the shredder through a conveyor belt or a hydraulic pusher.

The feed port is usually equipped with a hydraulic pressing device to push the material into the crushing area through reciprocating motion.

Crushing:

Double-axis shearing crushing: There are two relatively rotating knife shafts inside the shredder, and the knife shafts are equipped with staggered moving knives and fixed knives.

The moving and fixed knives break down large furniture into small pieces through shearing, tearing and squeezing.

The knives are designed with spiral or staggered teeth to enhance shearing efficiency.

Discharging:

The crushed material is discharged through the screen, and the screen aperture can be adjusted according to the discharge requirements (usually 10-100mm).

The material that does not meet the particle size requirements will return to the crushing chamber for further processing.

| Model | Overall Size(mm) | Crushing Cavity Size(mm) | Power(kw) | Weight(kg) |

|---|---|---|---|---|

| XRD - SZSS - 500 | 2800×1300×1850 | 500×480 | 11×2 | 2200 |

| XRD - SZSS - 800 | 3000×1300×1850 | 800×480 | 15×2 | 2500 |

| XRD - SZSS - 1000 | 3300×1900×2200 | 1000×690 | 22×2 | 5200 |

| XRD - SZSS - 1200 | 3600×2000×2200 | 1200×690 | 30×2 | 6400 |

| XRD - SZSS - 1500 | 4100×2100×2400 | 1500×850 | 55×2 | 9000 |

| XRD - SZSS - 1800 | 5800×2400×3300 | 1800×1206 | 75×2 | 13600 |

| XRD - SZSS - 2000 | 6400×2700×3500 | 2000×1490 | 90×2 | 20100 |

| XRD - SZSS - 2500 | 7500×3200×3800 | 2500×1800 | 110×2 | 22500 |

| XRD - SZSS - 3000 | 8600×3500×4000 | 3000×1800 | 160×2 | 31000 |

(Special - customized types can be customized according to the size and type of materials.)